PRODUCTS

- Home

- Applications

- Silicon and Compound Semiconductor

- Wafer Manufacturing

- VISION 200/300-M

VISION 200/300-M

DipView

Advanced Features

• High measurement speed < 10sec

• Best lateral resolution : <60mm on 300mm

• Full field of view for 200mm or 300mm

• Dual side measurement / No stitching

• Manual wafer loading on tray

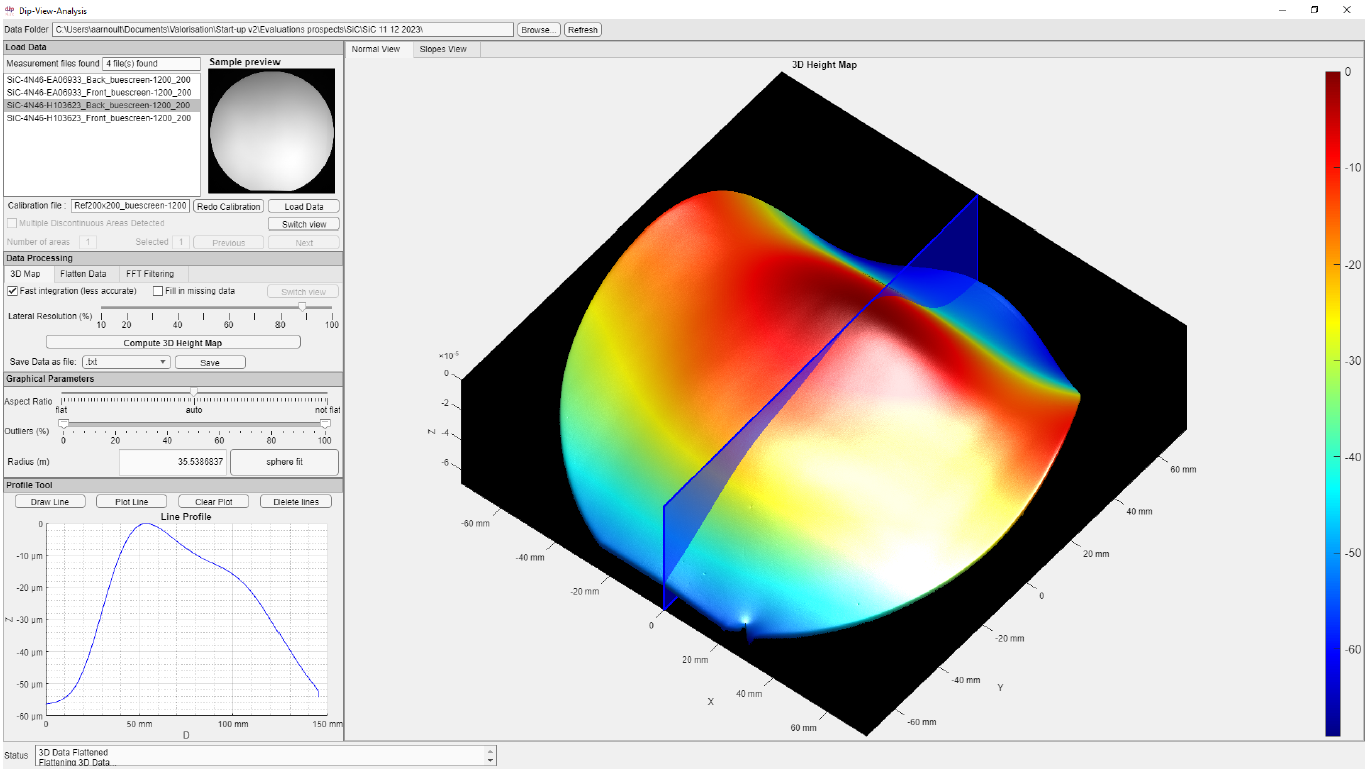

• Software: Easy-to-use software interface

Software Features

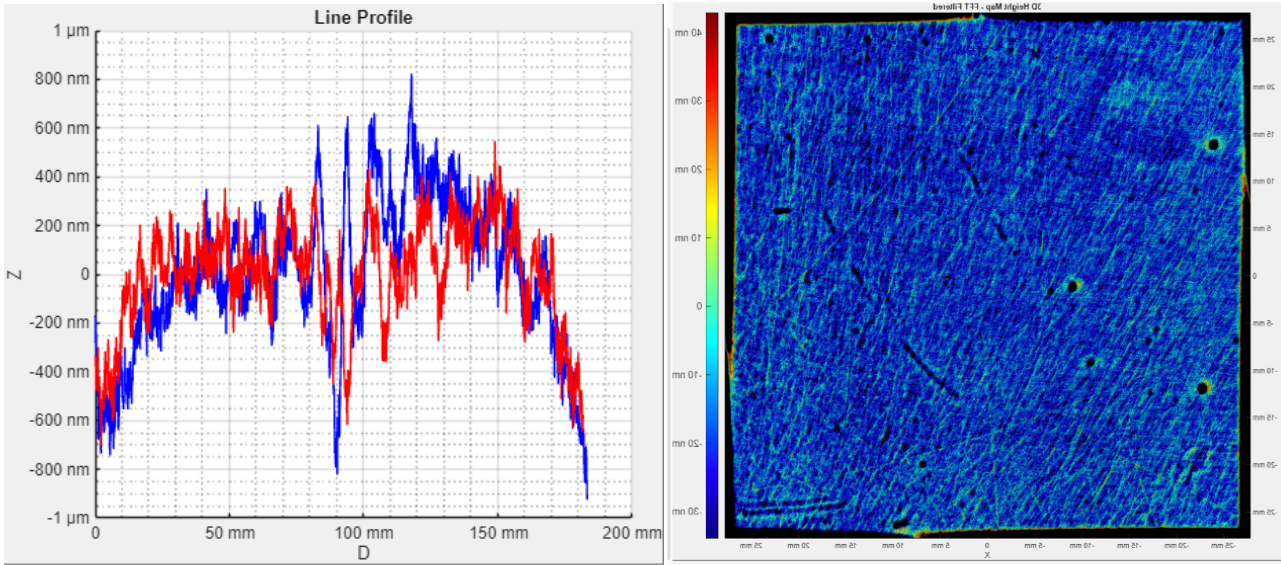

| Key Metrology Parameters | Flatness, line profile, surface profile, roughness, filtered surface, flattened surface roughness, polynomial fit | |

| SEMI compliant parameters | Bow, Warp, TTV, LTV, SFQR | |

| Normalized roughness parameters | Sp, Sv, Sz, Sa, Sq, Ssk, Sku | |

| Export format |

By default: txt, obj, csv. |

Open format – Custom formats |

| Computer | PC based – Linux Web interface | |

Key Applications

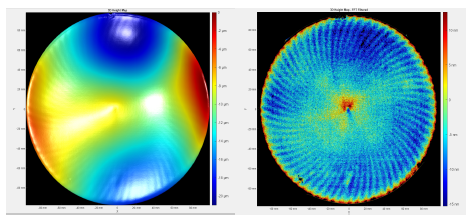

• Metrology : bow, warpage, TTV, LTV

• Roughness and Nano-topography analysis

• Wafer Manufacturing process optimization (sawing, grinding, CMP,..)

• Warpage in Front-End and Advanced Packaging

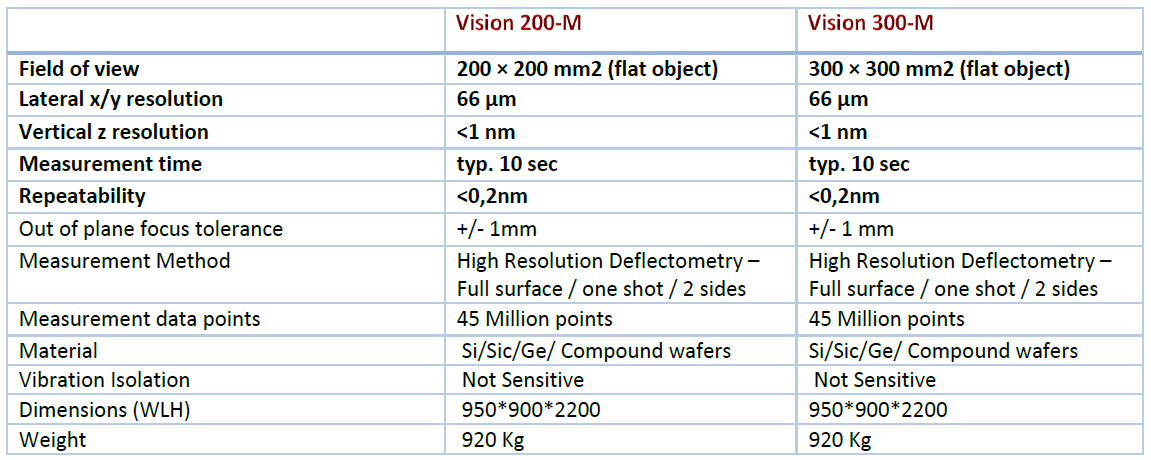

Measurement Technical Characteristics