2025.12.10

BlogsG&N Precision Concrete Surface Grinding Solutions

— Precision in Perfection, Made in Germany —

G&N is a German manufacturer specializing in high-precision grinding equipment for material testing, quality inspection, and civil engineering research.

Our systems ensure concrete specimens meet EN 12390-1 flatness and parallelism standards, improving accuracy in compressive strength testing.

| BS1 plus|Concrete Surface Grinding Machine |

MPS E200 Eco –|Precision Surface Grinding for Concrete Specimen Preparation | ||||

|

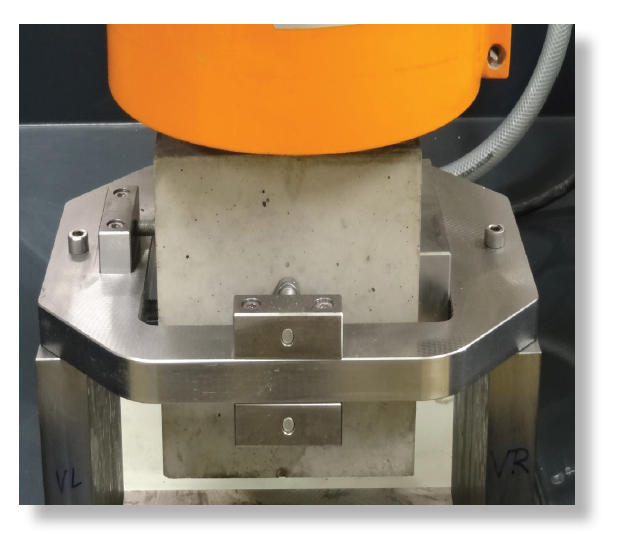

Engineered for Perfect Specimen Preparation in Compressive Strength Testing The BS1 plus is designed specifically for the plane-parallel grinding of concrete specimens, ensuring the highest level of accuracy for compressive strength testing. Benefits .Efficient plane-parallel grinding for accurate compressive strength testing .Precise preparation of standardized concrete specimens .Compatible with multiple clamping frames for various applications .Easy and intuitive operation .Low maintenance thanks to robust German engineering Features .Siemens TP700 Comfort HMI panel .Integrated loading and unloading device .Coolant supply system .Automatic fine adjustment (min. step 5 μm) .Hand shower for convenient cleaning Technical Data .Motor power:3.3 kW .Connecting power:4 kVA .Spindle speed:2850 min⁻¹ .Rotary table:Ø 320 mm, 5–30 min⁻¹ .Plane parallelism:according to EN 12390-1 .Grinding wheel:Ø 200 mm .Grinding height:320 mm .Fine infeed:300 mm range, min. step 5 μm .Total weight:410 kg .Dimensions (L × W × H): 1148 × 1133 × 1744 mm

Made in Germany |

German-engineered reliability for accurate and consistent compressive strength testing The MPS E200 Eco – Concrete is a precision grinding machine designed for preparing the end surfaces of concrete specimens. Benefits .Efficient plane-parallel grinding for accurate compressive strength testing .High-precision fine infeed for superior flatness and parallelism .Easy handling with intuitive operation .Low maintenance thanks to robust German engineering Features .Basic device for holding different tenter frames for versatile specimen sizes .Coolant supply system to maintain grinding stability .Height adjustment mechanism for easy setup and precise positioning .Integrated splash guard for safe and clean operation .Rigid machine base ensuring excellent stability .Three-phase motor delivering reliable and consistent performance Technical Data .Drive motor:3.3 kW .Connection power:5.5 kVA .Spindle speed:2850 min⁻¹ .Flatness of machine table:≤ 0.02 mm .Plane parallelism:according to EN 12390-1 .Grinding wheel:Ø 200 mm .Grinding height above machine table:320 mm .Fine infeed:165 mm 行程 .Total weight:340 kg .Dimensions (L × W × H):1148 × 1133 × 1744 mm Made in Germany |

||||